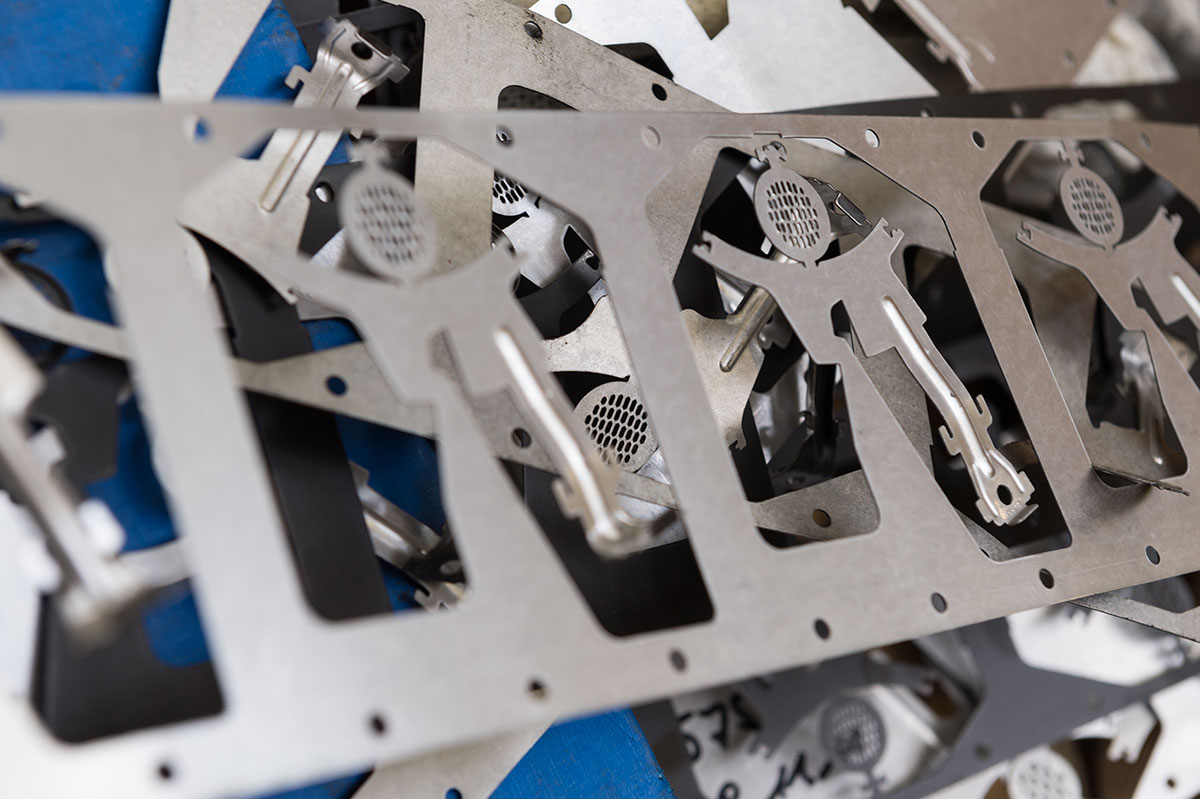

Precise stamped parts and stamped-bent parts for every need

We offer everything from a single sourceAs an experienced manufacturer of stamped and stamped-bent parts in Germany, SIV stands for maximum precision, flexibility and vertical integration. Thanks to the close connection to the HUEHOCO Group, customers benefit not only from comprehensive expertise, but also from an end-to-end production process: from coated metal strip to ready-to-install components – all from a single source.

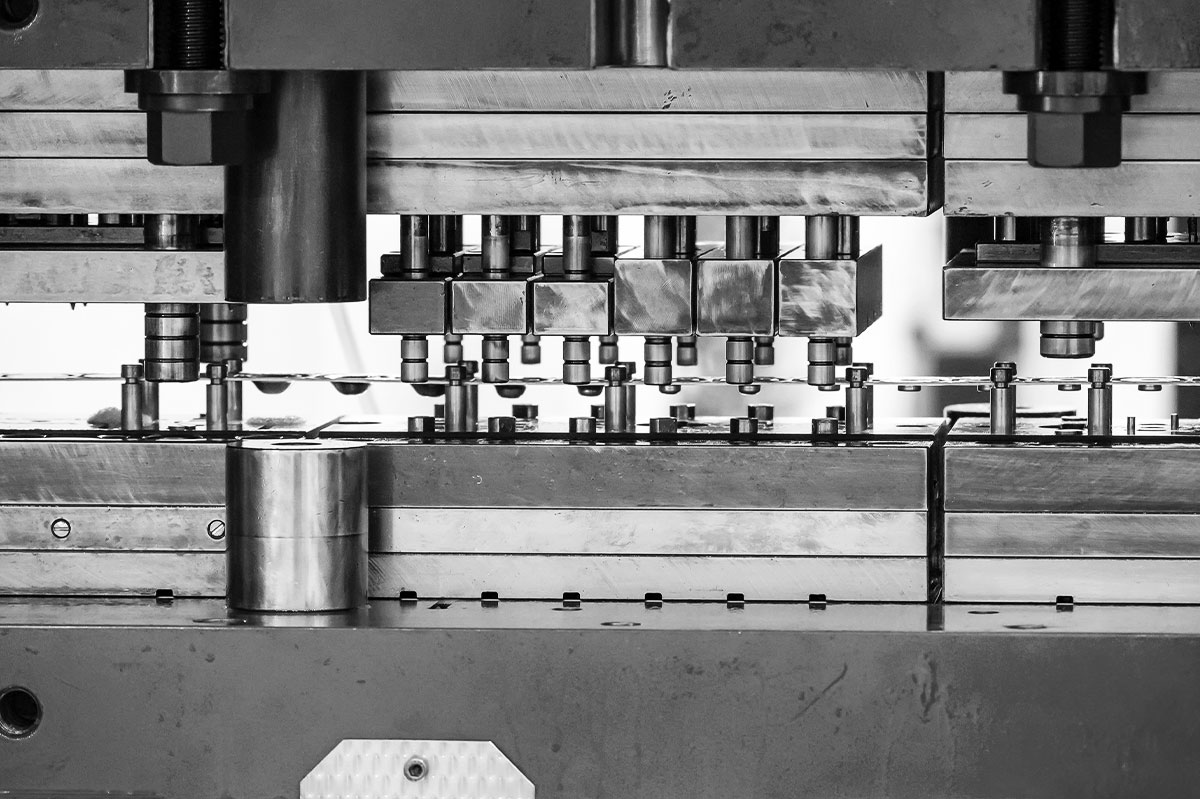

Modern punching and bending technology offers you advantages in terms of precision and efficiency

Our highly automated stamping and bending systems enable the economical production of complex stamped metal parts – whether stainless steel, spring steel, aluminum or coated primary material. We rely on the latest machine technology, seamless process monitoring and maximum repeat accuracy. We design and manufacture individual progressive tools in-house in our own tool and mold making department – quickly, efficiently and precisely. This allows us to react flexibly to prototypes or small series and guarantee maximum service life for series production.

Your advantages at a glance:

- In-house tooling for short response times

- Fast implementation of changes for product adaptations

- Maximum dimensional accuracy & stability – even with complex geometries

Customized stamped parts for your industry and application

We know that every industry has its own requirements and that your particular application is unique. That’s why we develop your stamped-bent parts as individually as your product – from the first prototype to series production. Our flexible production and close cooperation within the HUEHOCO Group make us the partner of choice for many demanding industries.

- Automotive industry

- Electrical engineering / electronics

- Mechanical and plant engineering

- Medical technology

- Building technology & household appliances

- Aerospace

Reliable quality from the conveyor belt to the component

SIV combines state-of-the-art stamping and bending technology with precisely matched coatings from the HUEHOCO Group. Our quality assurance starts with the metal strip and ends with the ready-to-install part – precise, reproducible, documented.

Perfection in every detail

SIV lives up to quality standards: from the strict incoming material inspection (mechanical tests, batch traceability) to the final stamping and bending step – we work with the highest precision. Thanks to optimized coil coatings that have been specially developed for the stamping process, the metal can be processed safely and accurately.

Reliable through integrated process chains

Because SIV is closely networked with HFP Strip Steel (cold rolled strip) and SI Coatings (surfaces), you benefit from ideally coordinated processes. In this way, we guarantee consistent material and process quality – without friction loss or interface risks.

Reliable group expertise

By accessing the bundled expertise of the HUEHOCO Group, you receive highly functional coated stamped parts, manufactured to strict specifications – for applications with high requirements, e.g. in the automotive or electronics sector.

General questions about stamped parts and stamped-bent parts

Whether in electrical engineering, the automotive industry or mechanical engineering: stamped parts and stamped-bent parts are used wherever complex metal shapes with high precision are required. They are created through the interaction of stamping and bending – two proven forming technology processes that are designed for high efficiency and flexibility.

The starting material is usually a cold-rolled or coated metal strip – such as stainless steel, spring steel or aluminum. The contours of the components are punched in specially developed progressive dies and then precisely bent. SIV uses state-of-the-art machines to guarantee the highest quality even for small batch sizes or prototypes.

The advantages are obvious: complex functions and shapes can be efficiently mapped and quantities are flexibly scalable – from small batches to mass production. At the same time, customers benefit from low production costs, short throughput times and the high resilience of the finished parts. Coated or surface-finished variants are also possible – e.g. as coated stamped parts for corrosion-critical applications.

Depending on the area of application, stamped-bent parts have very different requirements in terms of strength, conductivity, corrosion resistance or dimensional stability – which is why materials such as stainless steel (e.g. for robust, temperature-resistant parts), spring steel (for flexible, stress-storing functions), aluminum (for lightweight components) or non-ferrous metals such as copper (e.g. for good electrical conductivity) are used depending on the application.

SIV actively advises you on the selection of the right material – tailored to your technical requirements, quantities and subsequent application. Coated or refined metal belts from the HUEHOCO Group are also available for special requirements.

Yes – SIV can also produce small quantities economically thanks to its own toolmaking department. We develop individual stamping and forming solutions for prototypes or pre-series in the early project phases. This accelerates development cycles, reduces modification costs and ensures that your subsequent series production processes run smoothly.

Depending on the area of application, stamped and bent parts can be provided with various functional or protective coatings. These include, for example, corrosion protection systems, electrically insulating coatings, anti-friction or non-stick coatings and heat-resistant special coatings. The coating systems are developed in-house within the HUEHOCO Group and are specially optimized for the stamping process – for maximum adhesion and formability.