Cold rolled steels

Many years of experience and state-of-the-art technologyWe offer our customers a wide range of cold-rolled steels – of the highest quality at competitive prices. In addition to a high degree of flexibility and readiness to deliver, we guarantee exact compliance with the specified chemical and mechanical values.

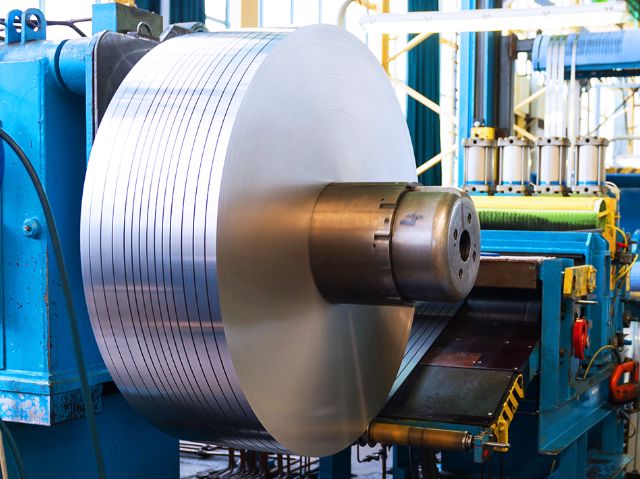

Surface finishing by electrolytic galvanizing and/or subsequent dimensional cutting is also possible for us. We offer all our customers coil systems with volumes of over 200,000 meters of metal strip per coil. This further development means a considerable advantage for our customers, because personnel-intensive setup times and machine downtime can be avoided.

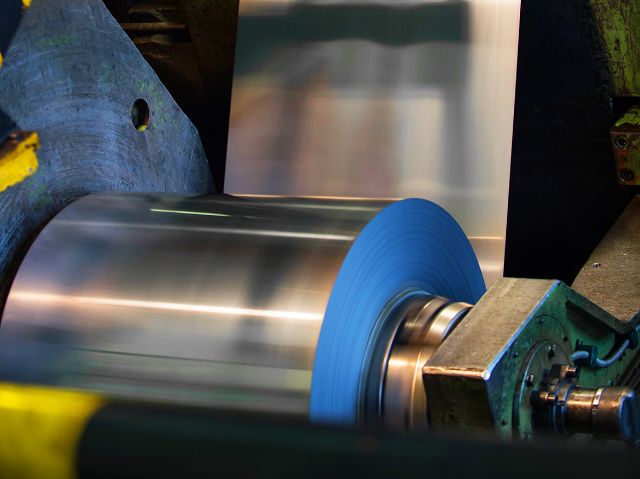

Process steps of cold rolling

All in one handAll process steps of cold rolling – from thickness reduction and heat treatment to re-rolling and subsequent finishing – are perfectly coordinated and continuously monitored by our quality and process management system. Our rolling stands are equipped with the latest technology and guarantee consistently high quality production.

Because the heat treatment of the steel is decisive for the material properties of the end products, we work with roller hearth annealing furnaces. In contrast to the more static bell annealing, these allow continuous homogenization of the metal structure.

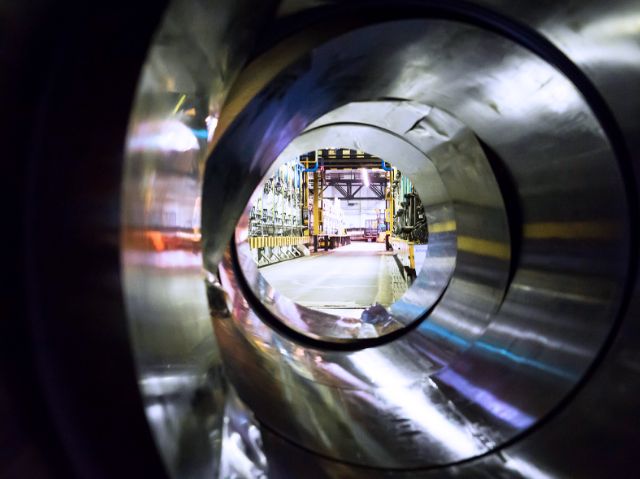

Coiled metal strips

More running lengthIn order to increase the running lengths, we join the metal strips using the latest welding technology and oscillatingly wind them onto new spools. In this way, we reduce set-up and downtimes in your production.

- Strip widths from 1.5 mm up to 60 mm

- Extension of the running length to over 200,000 meters in one core depending on the material

- Individual installation widths from 100 to 400 mm

- Special decoiling racks with winding widths of 800 mm and maximum winding weights of 2,500 kg